The robots Are Coming?

November 3, 2025

Jay RameySome automakers are experimenting with humanoid robots. Are they potentially useful? At what cost?

Elon Musk raised plenty of eyebrows in the business world with the launch of the Optimus program. But Tesla was merely going where other automakers have been before, albeit in a different era, one increasingly defined by the hopes heaped with increasing desperation on AI.

Lest we forget, Honda’s own Asimo robot was dancing and playing musical instruments long before the first Tesla hit public roads.

Maybe Honda was merely too early with its Asimo robot, which was launched all the way back in the year 2000 after about a decade and a half worth of research. It was shelved in 2018, perhaps too early once again.

In that span of time the industry has seen the rise of Boston Dynamics, whose robots seemingly grew in capability with each passing year during the 2010s, evolving from clunky, mule-shaped quadrupeds powered by small and noisy gasoline engines, to humanoid robots that became viral Youtube stars while performing parkour tricks, if not exactly doing anything of business value.

But a business case for humanoid robots remained elusive for much of that time, even as Boston Dynamics found a a few supporting roles for its Spot robot, often venturing into places where human workers might face a tough time. The dog-shaped robots have taken on inspection and surveillance work in a number of settings, seemingly finding a narrow niche in industrial settings where size matters, but the device still requires plenty of supervision.

But what about humanoid robots — could they become just a part of the landscape as quickly as delivery robots have begun to pepper sidewalks in European capitals and American college campuses?

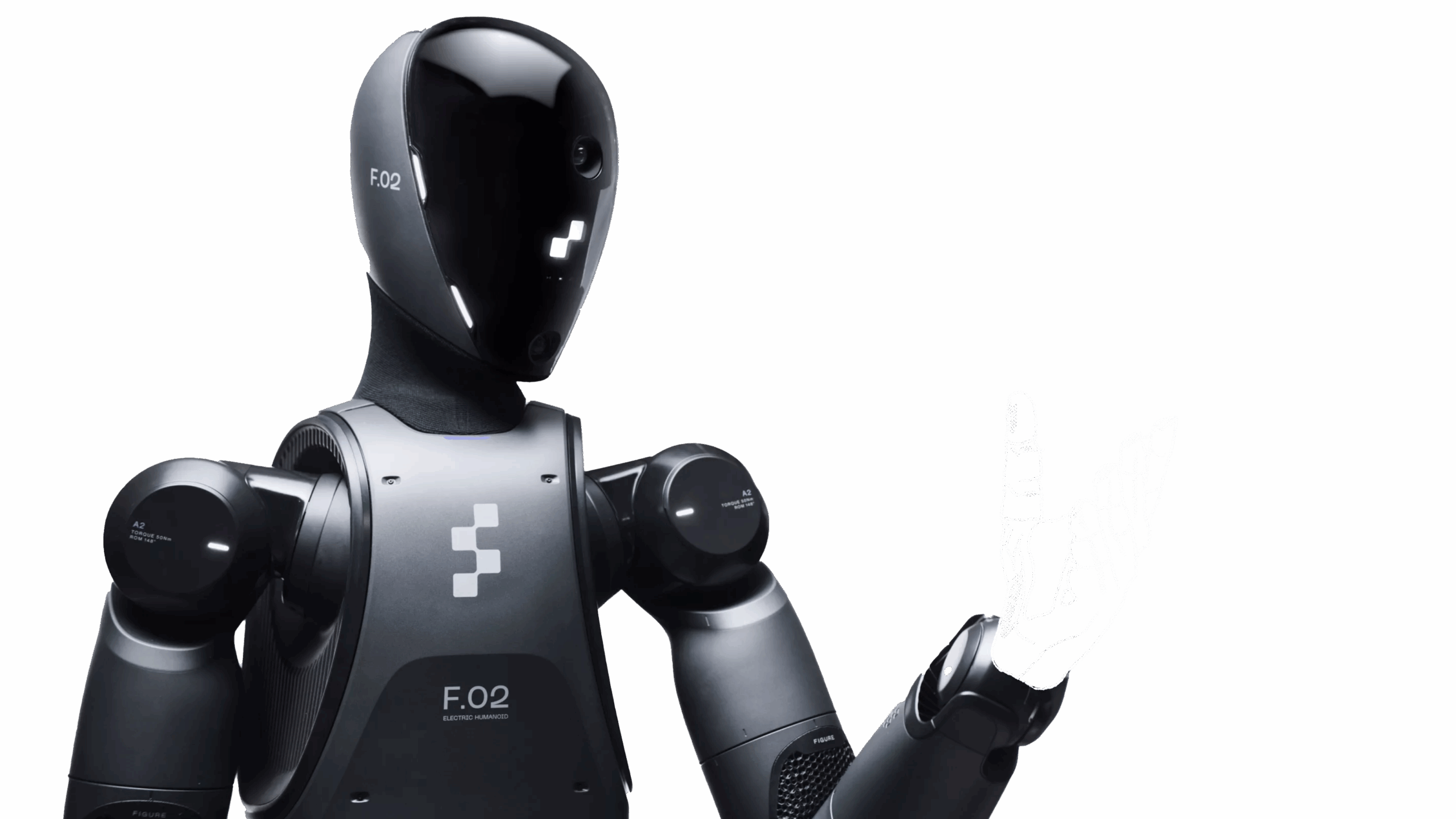

A handful of automakers are betting that the next few years could see humanoid robots deployed en masse in everything from warehouse to factory settings, and Tesla is far from the sole automaker gambling on this future.

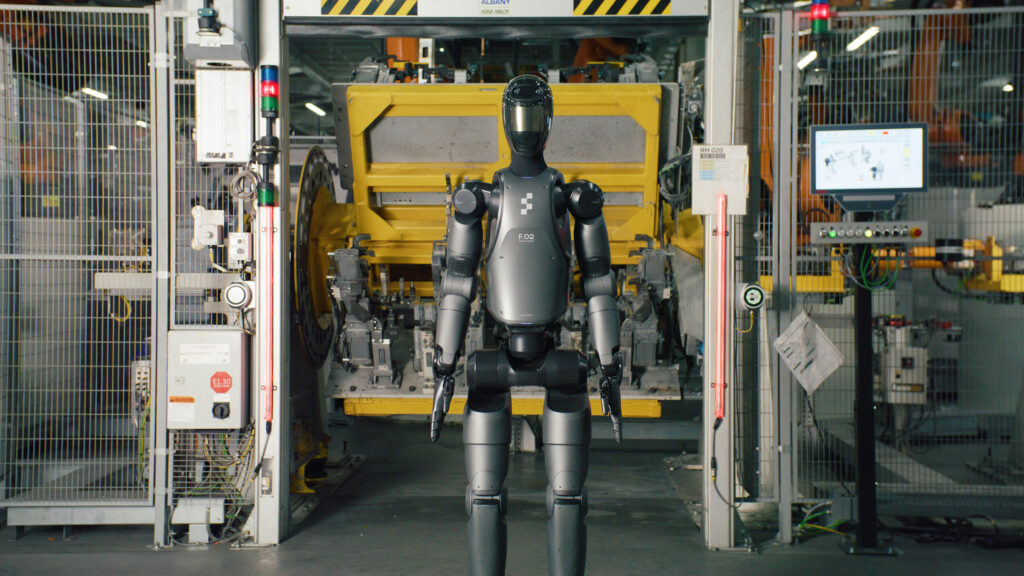

Mercedes-Benz has recently teamed up with robot developer Apptronik, which got its start in Texas nearly a decade ago, while Hyundai has revealed plans to produce Boston Dynamics’ latest Atlas robot in-house after buying the US-based startup in 2021, in what now seems like a particularly prescient move. BMW is hopeful as well, having been testing robots by startup Figure at its Spartanburg factory.

“The developments in the field of robotics are very promising,” said Milan Nedeljković, Member of the Board of Management for Production at BMW AG. “With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization.”

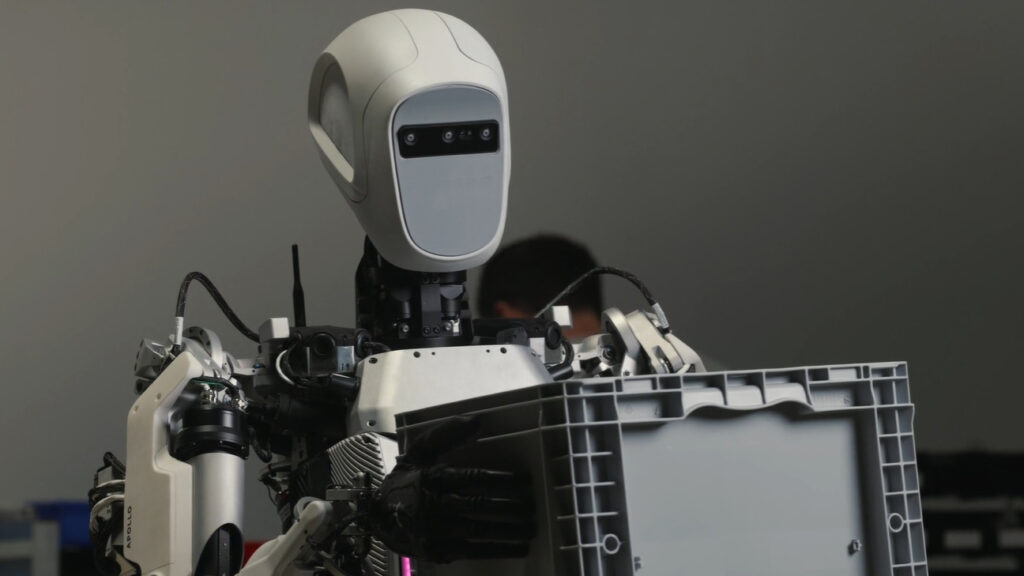

Likewise, Mercedes-Benz has been optimistic about humanoid robots’ potential for factory work while carrying out tests of its own. For now, Mercedes’ plans for Apptronik’s Apollo are fairly limited, with the robot being tasked with delivering parts to the assembly line and performing similar tasks that do not require much dexterity, intricate coordination, or finger work.

Hyundai’s plans for robots at the moment are perhaps the most ambitious of all. Earlier this year the automaker revealed plans to build robots in-house, using its own production base, and to deploy them in car factories en masse alongside humans.

“Robots take on tasks that are repetitive, hazardous or physically demanding, allowing humans to focus on high-value work that requires creativity and innovation,” the automaker said regarding the robots’ potential earlier this year.

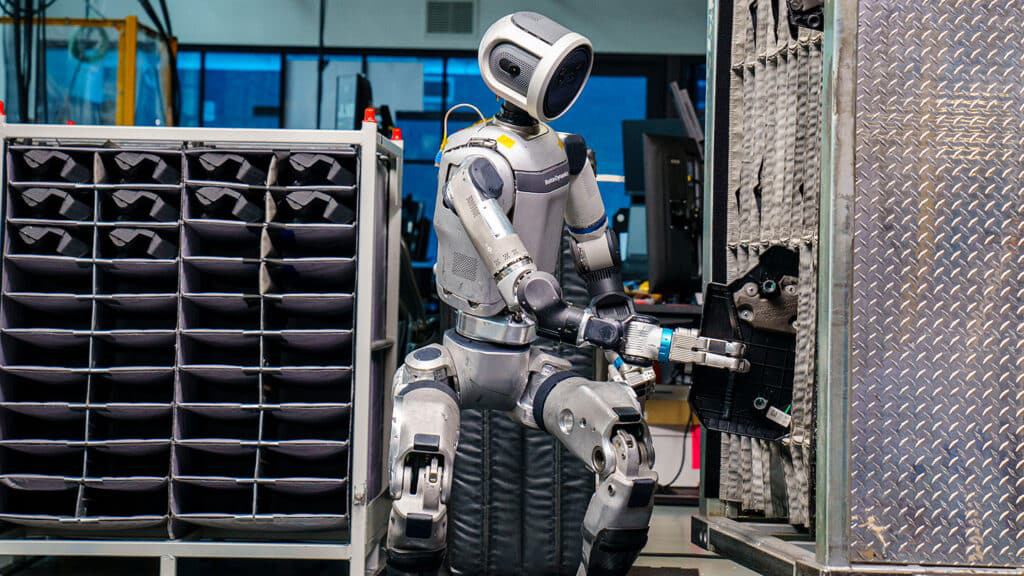

Hyundai and Boston Dynamics’ Atlas robot is still under development, with the automaker recently announcing plans for a US-based robotics research and production hub with a 30,000-unit annual capacity.

But are these robots ready to do anything useful in factories, aside from being able to pick up light cardboard boxes and slowly carry them a few yards?

There are still plenty of reasons for skepticism in this sphere, with a number of industry observers warning that humanoid robots are still very much in the hype stage, and aren’t likely to learn to manipulate small objects any time soon, limiting their usefulness to manufacturers.

And it’s a problem that won’t be solved by Large Language Models (LLMs) or other types of AI.

Rodney Brooks, one of the best-known robotics experts, has been sounding the alarm on the current moment of humanoid robot hype in the industry, while pointing out serious limitations that aren’t likely to be solved through teleoperation or other mechanical means. The limitations boil down to the dexterity and touch receptors in human hands essential for minute tasks, but ones that cannot be replicated by robots.

“No human-like robot hands have demonstrated much in the way of dexterity, in any general sense,” Brooks writes. “And none have inspired designs that have made it into deployment in real world applications. The approaches to dexterity have been very mathematical and geometrical, and they have just not produced anything like human dexterity.”

Brooks has also poured cold water on the idea of using videos to train robots to perform more complex tasks, as robot developer Figure AI has done in an effort to bridge this gap.

“In a few cases humans teleoperate a robot, that they can see, along with the objects being manipulated, and the humans may get a tiny bit of force and touch feedback–mostly it comes from the hands of the robots and not the wrists or elbows or shoulders or hips, and any such touch data is very crude,” Brooks adds.

Likewise, critics have pointed out the limited use cases of humanoid robots in factories, versus simpler wheeled logistics bots that currently scoot around factory floors.

For the most part, there is a vast gap between what car factories might actually require, and what the current crop of humanoid robots can actually do.

Installing a wiring harness under the dash of a car is out of reach at the moment, as is handling any small components — a task only humans can do on the assembly line. A task as simple as accurately operating a screwdriver is also beyond the ability of humanoid robots.

Perhaps this is one of the reasons we only see robots handling cardboard boxes in various videos showcased so far. But even in a logistics warehouse there are specialized robotic systems more adept at sorting items into boxes than the robots’ hands and fingers allow.

Where does this leave the prospects of using humanoid robots in factories?

Despite the seeming gains in acrobatics by humanoid robots over the past decade, skeptics point out that the current moment is being driven largely by investor optimism rather than business use cases or a path to scalability, and a perception of progress in the media space surrounding robots.

These skeptics now include Chris Walti, the former lead of the Optimus robot program at Tesla, who cautions that current focus on the human form factor is not ideal for repetitive tasks in industrial settings, and that specialized robots used in jobs like moving pallets or welding are far more suited to today’s factories than anything human-shaped.

As robot hype and AI hype converge in the next few years, it will be important to note just what kinds of jobs, besides awkwardly picking up light cardboard boxes, humanoid robots will actually be able to do, especially without supervision or a whole software team watching their every move.

Recent Posts

All PostsMarch 6, 2026

March 6, 2026

March 5, 2026

Leave a Reply