Foreign Relations

February 18, 2026

Alex KiersteinFord’s upcoming low-cost EV pickup truck is an interesting mix of state-of-the-art engineering and licensed Chinese tech. This has geopolitical implications.

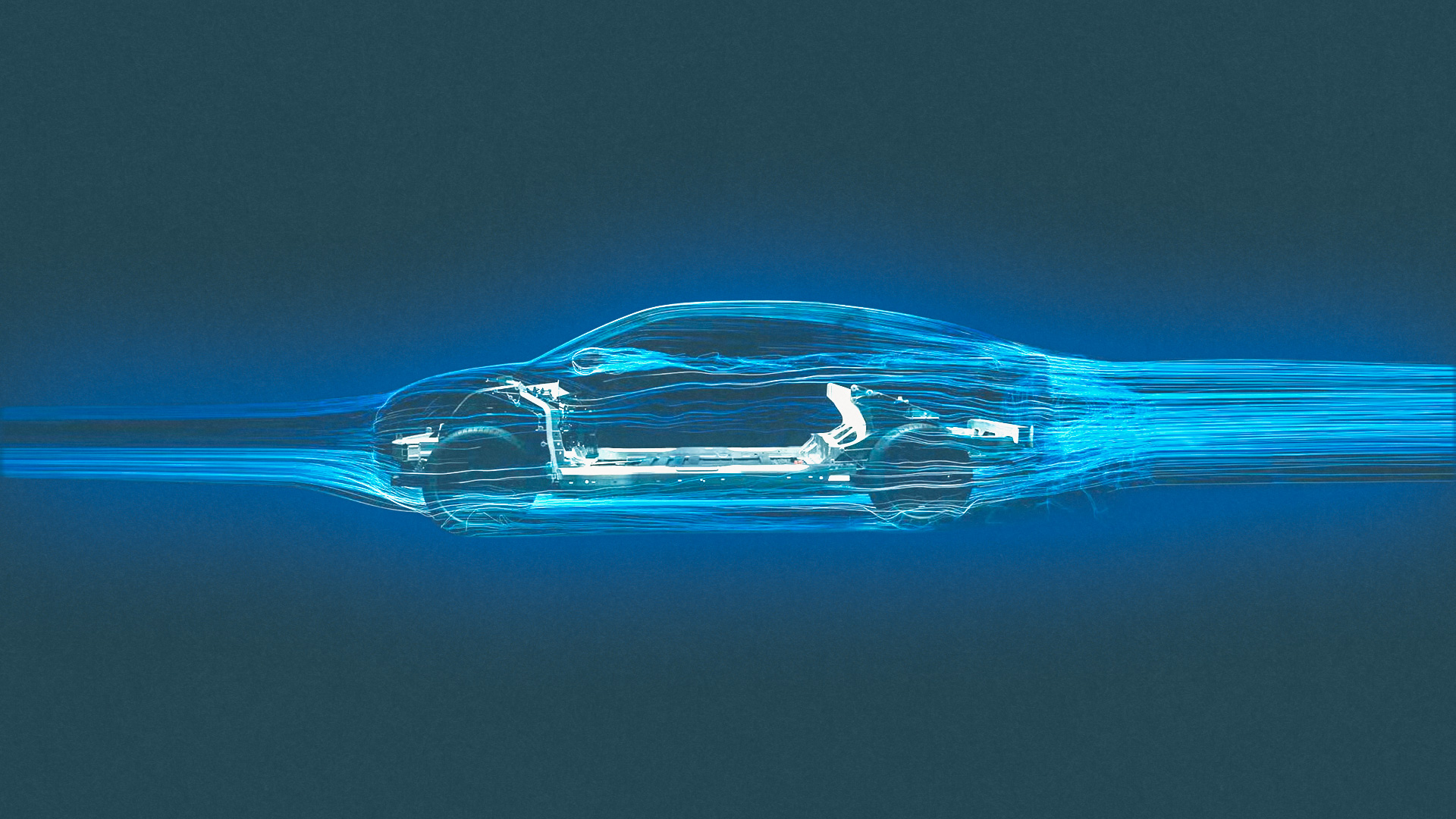

A few weeks ago, I wrote about a fascinating Autocar piece that explored cell-to-body (aka cell-to-structure) EV architecture developed by Chinese companies—essentially eliminating the battery housing as a separate element that is bolted into the unibody, instead creating a well in the unibody for the battery cells to fit into. It reduces complexity and cost quite significantly, but European automakers are way behind in adopting it. So it’s very interesting (and, on some level, unsurprising—more on that in a minute) that Ford’s upcoming low-cost “Universal Electric Vehicle” EV architecture will utilize cell-to-body architecture. A new video the company put out highlights this and some other interesting aspects of the as-of-yet-unseen small truck.

Let’s start with the battery. It’s a lithium-iron-phosphate (LFP) pack, housed underneath the floor in a well between the side frame rails. The central part of the structure of the vehicle is relatively simple. It’s two large longitudinal frame rails, between which is suspended an integrated battery case (with its own perimeter frame) and to which the two subframes attach. The upper cover, which forms the vehicle floor, contains all of the circuitry and connections between the cells, eliminating separate bus bars and so forth. Aft of the pack is an integrated DC/DC converter and AC/DC charger, which also charges the low-voltage battery. It’s a little like the integrated ICCU in E-GMP vehicles. (Hopefully without that unit’s issue with failures.)

The electric architecture is 400V, which enables relatively quick charging but doesn’t match the 800V architecture of mid-range EVs like some of Hyundai/Kia’s E-GMP vehicles. It’s inline with the more widely available 400V systems in competitors like the GM and Volkswagen EVs. Like the LFP battery, it’s a lower cost solution, allowing for still-fast but not ultra-quick DC fast charging.

It also will use a 48V “low-voltage” architecture, which has several advantages, one of which is a significant reduction in the amount and size of copper cable in the vehicle. A zonal computer architecture also helps, reducing the total number of ECUs and thus connections. Each ECU can handle several functions, rather than having a dedicated ECU to control the climate control and another one to handle seat controls. Put both functions on the same board, is the idea. Many automakers are moving to zonal architecture. I remember being at a Rivian event a while back in which it had a big mass of copper wire weighing (if I remember correctly) around 30 pounds, to illustrate how much mass and cost it was able to pull out of its zonal architecture vehicles.

Finally, the other interesting bit in the video is the large aluminum castings that form single-piece front and rear subframes. One of the engineers points out that the front and rear subframes on the Maverick are comprised of 146 individual parts and fasteners, while the large “unicastings” on the upcoming EV truck are a single piece, each. That’ll require 25 percent fewer fasteners, Ford says. I have no idea what the cost delta is between the Maverick’s conventional subframes and the upcoming truck’s unicastings, but there has to be a significant weight reduction.

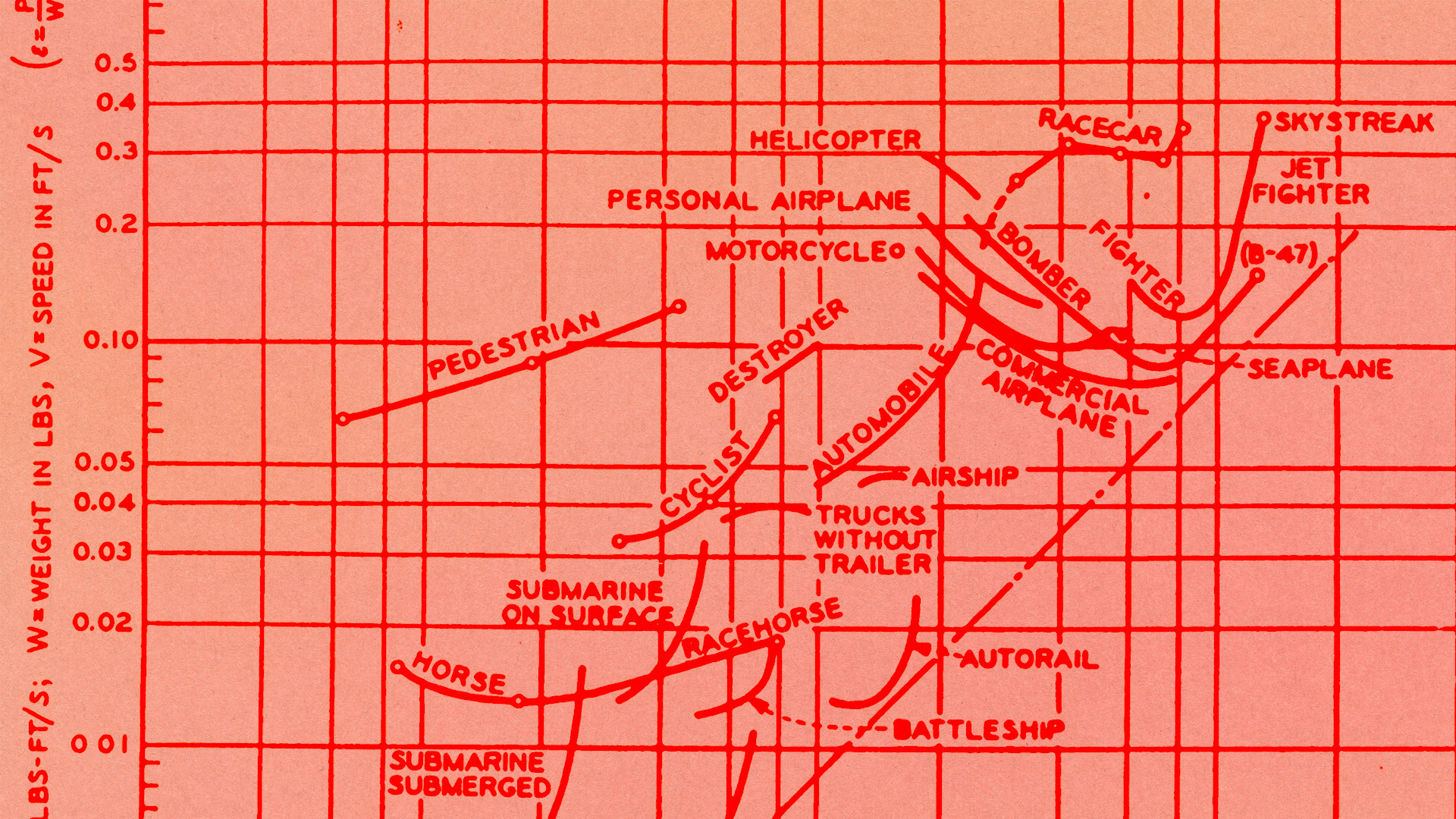

Batteries are an extremely expensive way to store energy at the moment. They are massive and have relatively low energy density compared to gasoline. As the video points out, reducing vehicle mass, aero drag, and frictional losses mean you can fit a smaller battery, saving unit cost. Even if the part is more expensive than a conventional one, if it offsets more battery cost, it’s a net win.

Of course, a large part of the cost savings here is that Ford doesn’t have to develop its own battery technology. It may own the plant in which the batteries are being assembled, but the technology is licensed from the Chinese battery giant CATL, who will also provide the expertise necessary to run the plant. At the moment, this seems to be an unavoidable outcome. Like other Chinese EV and battery makers, it is significantly farther ahead than our domestic producers in terms of technology and packaging.

It doesn’t seem likely that Ford could do a mass-market midsize EV truck without a Chinese tech and know-how even without the current administration’s hostility towards EVs. And yet, last year the US Department of Defense (or is it the Department of War?) designated CATL a military company. That invites additional scrutiny of any dealings with the company, discourages the military from acquiring anything utilizing its tech or components, and has prompted politicians to call for American automakers to have fewer ties with the company. Ford, in particular, has been highlighted for its rather direct relationship with CATL in the BlueOval Battery Park facility that will produce the LFP packs for the truck.

That makes Ford’s UEV truck a strong real-world example of the inability of American automakers to separate their EV plans, whatever remains of them, from a supply chain and knowledge base that is almost solely based in China. And without indigenous investment and willpower for EVs in America, that won’t change.

Recent Posts

All PostsFebruary 20, 2026

February 19, 2026

February 18, 2026

Leave a Reply